Almost 35 years have passed since the first time that sustainable development was discussed, when in 1987 the World Commission on Environment and Development approved the preparation of the Report “Our Future in Common” led by Dr. Gro Harlem Brundtland, Prime Minister of Norway by then. In this report, what many already knew was recognized: ” It is in the hands of humanity to make development sustainable to ensure that it meets the needs of the present without compromising the ability of future generations to meet their own “, that is, the need to change the approach with which economic activities were developed in a system at that time, based on the belief that growth has no limit. A new development model arises that proposes to be that “development that meets the needs of the present without compromising the ability of future generations to meet their own needs”.

Image: “Gro Harlem Brundtland presenting ‘Our Common Future’ at UN”.

Source: www.eh-resources.org

However, in this time the world situation has radically changed. “Sustainability” is no longer a new word, much less, unknown or alien to the majority of the population. But as in most cases when something becomes popular, its indiscriminate use has left it empty of meaning. What really is sustainability? How can you be sustainable? From an ecological point of view, sustainability refers to the balance of a species with the resources of its environment. By definition, for this to happen, three principles must be met:

- Never consume a renewable source at a rate higher than its natural renewal.

- Never consume a non-renewable source without having used part of your energy to develop an alternative source that meets the same needs.

- Never generate any waste that cannot be assimilated in the corresponding sump and naturally inert.

However, the definition itself is not sufficient by itself: How can one guarantee that equilibrium is maintained when the magnitude of what is being measured is unknown? Sustainability by itself is not an adequate objective, especially when we ask ourselves the questions “What should we sustain?”

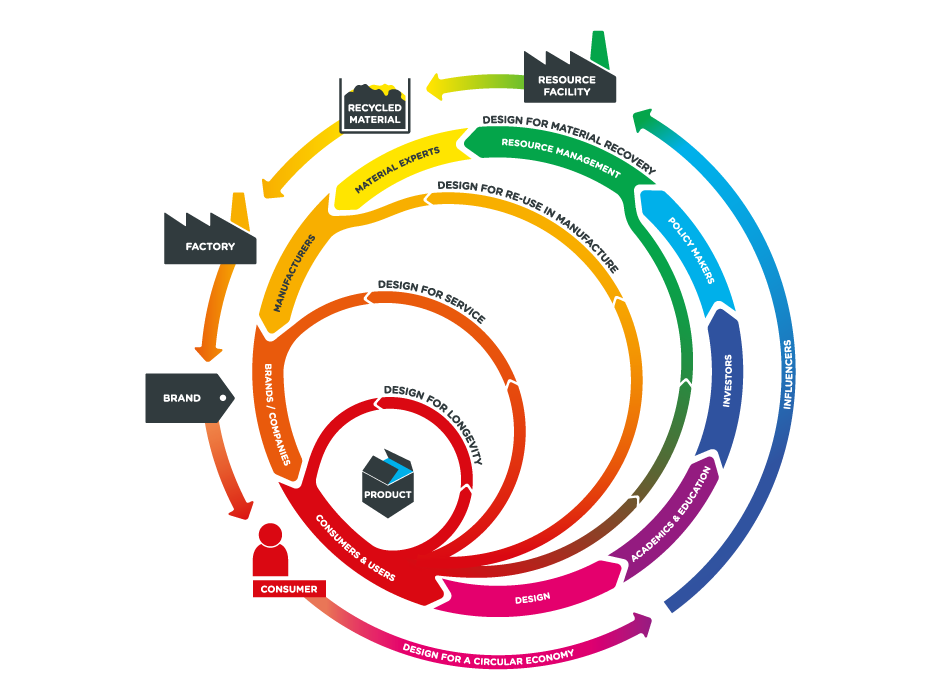

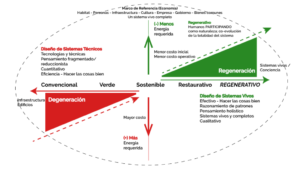

From a systemic perspective, what we are trying to sustain is the pattern that connects and reinforces the entire system, but what elements are we considering? Differentiating between a linear system (such as the current “make-use-throw” production system) and a circular one (known as “from cradle to cradle”) is essential, since the results that we will obtain by maintaining these two systems they will be radically opposite. With the first we will be able to not cause more damage than the current one, however, with the second we will be able to redirect the situation in which we live to generate conditions that make possible the future towards which we really want to go.

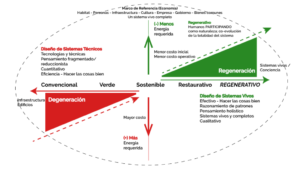

The key to understanding this comes from the hand of biologist Daniel Wahl, developer of a concept that has been gaining momentum in recent years: regenerative development. From agriculture to economy, from design to urban planning … the main idea is to create the conditions conducive to life with our performance. An idea taken from the functioning of nature itself and its ability to develop increasingly complex and diverse ecosystems, at all levels and scales, from the local, to the global, passing through the regional.

Image: “Degenerative systems and regenerative cultures”.

Source: https://laeconomiacircular.com/escuelas-de-pensamiento/

We are so used to solving problems that rarely do we stop to rest, take a breath and gain momentum, much less do we stop to question our way forward. However, dreaming is one of the most important activities to do when we talk about being sustainable. Dreaming, imagining a future and visualizing what do we really want to achieve? Well, if we do not change the model, no matter how much we change the origin of the raw material or measure our impacts, we will not truly achieve a future compatible with life.

But to create a true regenerative economy, we need to delve into the problems that are studied and the processes that are being improved in order to create changes that are truly transformative from current models to circular models. It is at this time that the Circular Economy is presented as the next link in this discovery process in which we find ourselves. Defined as “a regenerative system in which resource input and waste, emission, and energy leakage are minimized by slowing, closing, and narrowing material and energy loops. This can be achieved through long-lasting design, maintenance, repair, reuse, remanufacturing, refurbishing, and recycling”, the circular economy allows us to consider a future in which what is excluded from design is the generation of waste, something so important in the fashion industry.

The Circular Economy was described for the first time in the nineties by Pearce and Turner with the aim of clearly defining the existing relationships between the economy and the environment, around a fundamental concept: reduce, reuse and recycle; however, time and its application have contributed to the enrichment of this school of thought and today its complexity is greater: Redesign, Reduce, Reuse, Repair, Renew, Recover and Recycle.

How do we want the fashion of the future to be? Or even how do we want the future to be? These questions are the cornerstone on which new projects are drawing strength and inspiration to find the perfect balance between humanity, nature and technology. The economic as well as environmental advantages of these circular systems have contributed to the fact that more and more companies are structured around circular business models and with their implementation, the social aspects, one of the main weaknesses of the Economy. Circular is gaining relevance. Even more so in a sector such as fashion, in which so many industries are involved and whose consumption is increasing at a dizzying rate due to the increase in population and the rate of production.

So back to the initial question: is sustainability enough? The answer is no, but it is a very good starting point to be able to create new societies and new models. Thinking about a healthy and healthy future is almost as important as correcting the excesses that have brought us to this situation. Everything else is our desire to innovate, to create, to discover; and that is within our reach.

By Blanca Gomara,

Sustainable Fashion Consultant, Blanca Gomara | Spain

Sustainability / Fashion

Founder of 360flab

Blanca is founder of 360flab, a consulting firm for sustainable materials for the fashion and textile industry specialized in circular design that collaborates through training and consulting with new brands that are born with a sustainable heart as well as with established brands that want to make the transition like Inditex, OMINA Foundation, Gioseppo, etc.

After graduating as a fashion designer, Blanca specialized with a master’s degree in Fashion Product Management at IED Madrid and an MBA, and is currently pursuing a Master in Business Innovation and Project Management at the University of Mondragón. She has developed several cooperation and development projects in the business field within the circular economy framework, among which Patata Collective and The Hopy Project stand out (a modular pattern system to enable the training of illiterate women in Tailoring, a profession of tradition male and forbidden to women, in the district of Calcutta).

She was named Ashoka Emergent Innovator in 2019.